First and foremost, air brakes are a critical component of any trucking operation. Importantly, they provide the stopping power needed to keep heavy loads from flipping and causing accidents. Additionally, they also offer control on downhill grades. Therefore, understanding how they work, their pros and cons, and maintaining them is critical for all commercial drivers. So, let’s dive into the question of “how do air brakes work?”

What are semi truck air brakes?

The air brakes on a truck work with the service brake system to stop and hold the vehicle. Moreover, they are used more often than the parking brake and can be found on all commercial trucks, regardless of size or weight.

How do air brakes work?

To begin, air brakes activate when the driver presses down on the brake pedal. This triggers a diaphragm within the master cylinder, which pushes hydraulic fluid into lines that connect to each wheel’s air chamber.

Thus, when this occurs, an equal amount of pressure release from all chambers at once. This pressure is applied directly to the brake shoes or pads located within each chamber. Furthermore, this causes them to grip the brake rotor’s surface, which is a part of the wheel hub itself. In this way, air brakes function similarly to disc brakes on a car or motorcycle.

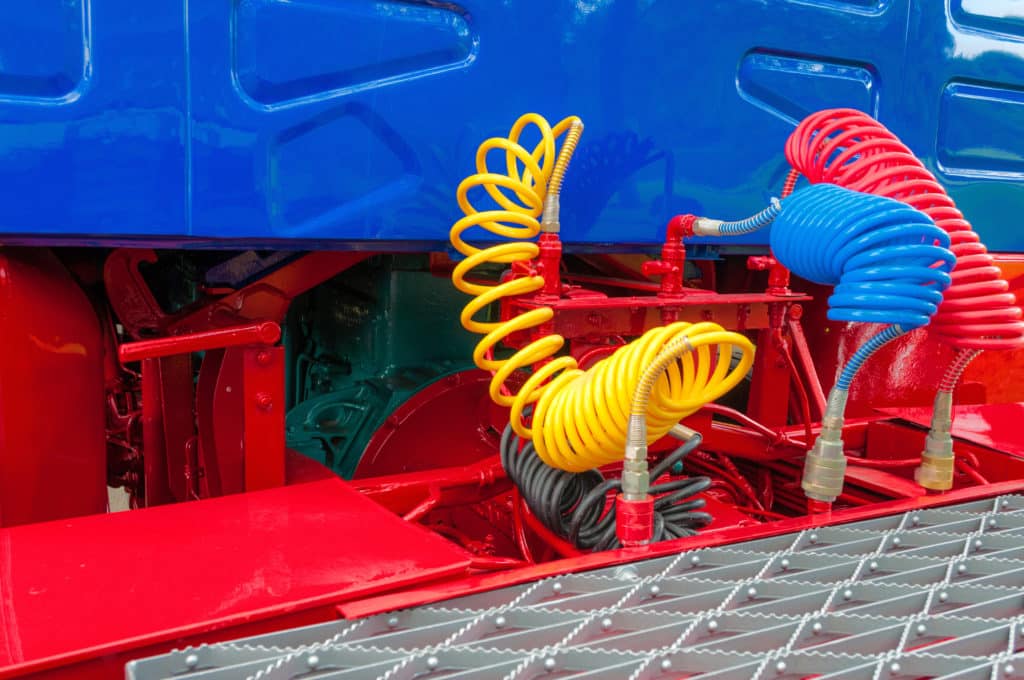

Semi Truck Air Brake Components

The following is a list of parts for an air brake system on semi trucks:

- Air compressor

- Drain valves

- Brake pedal

- Air compressor governor

- Brake chambers

- Pushrod

- Air reservoir tanks

- Slack adjusters

- Brake S-cam

- Brake shoe

- Return spring

In general, understanding the components of semi truck air brakes is the key to make sure you keep your brakes in good working order. Thus, if there is a problem with one of these components, it will cause significant problems for your braking ability and will need repair immediately!

Why do semi trucks use air brakes?

Resources and their accessibility and dependability are huge factors. Air brakes are more likely to be used as the vehicle gets heavier. Therefore, only service centers can manually refill tiny car brake lines with hydraulic fluid. (Unless you know how to do it yourself.) Best of all, the air utilized in semi truck air brakes is available all around!

The importance of understanding and caring for air brakes cannot be overstated.

Ultimately, a semi truck driver who does not understand how these brakes work can put themselves, their cargo, and others at serious risk.

Importantly, maintaining air brakes is critical for ensuring that they work correctly every time you need to slow down or stop. Therefore, an essential part of maintaining a commercial vehicle is knowing how to adjust these brakes properly. If this is not done correctly, you can lose control at high speeds or even damage them beyond repair if you’re going too fast.

Air Brake Maintenance and Care Tips.

Overall, air brake maintenance is not hard to understand. However, it’s important to be very careful about how you make any adjustments to the system – there are precise measurements for everything. Therefore, if you’re off by even a fraction of an inch or ounce, your brakes may no longer work properly.

At a minimum, semi truck air brakes should be checked regularly to ensure they’re functioning correctly. Other maintenance tips include:

- Checking air compressor pressure levels

- Replacing faulty or damaged components as needed

- Ensuring that there is plenty of brake fluid to refill the reservoir tanks. This should be done every time you top off your hydraulic oil supply.

- Check the compressor for leaks and wear on belts or hoses.

- Inspect all connections for any signs of corrosion or problems with mounting hardware

- Ensure there are no fluid leaks anywhere within the system; if you find one, repair it immediately.

- Check the condition of brake shoes to ensure they are not excessively worn or have cracks.

- Ensure that all slack adjusters and return springs/cables work correctly / smoothly before getting behind the wheel. You should be able to release your foot from any pedal position without resistance but with enough tension for you to feel confident that the brakes will engage when you need them to.

- Inspect pushrods regularly so they do not bend or warp; replace as needed.

These are just a few of the maintenance tips for semi truck air brakes. If you’re not sure how to do any part of this, don’t risk it!

Importance of Semi Truck Air Brakes

In conclusion, semi truck air brakes are a necessary safety precaution for any driver and can be expensive to repair if they fail. However, with the proper maintenance, you’ll be able to avoid costly repairs and keep your semi truck safe on the road.

We hope this article has helped answer your questions of “how do air brakes work?” and gives you more confidence in taking care of your rig on the road and beyond. So, if you ever find yourself in need of roadside assistance in Utah or Wyoming, get in touch with Bozz Towing!

Read More: